In-Depth Analysis On The Ready Mixed Concrete

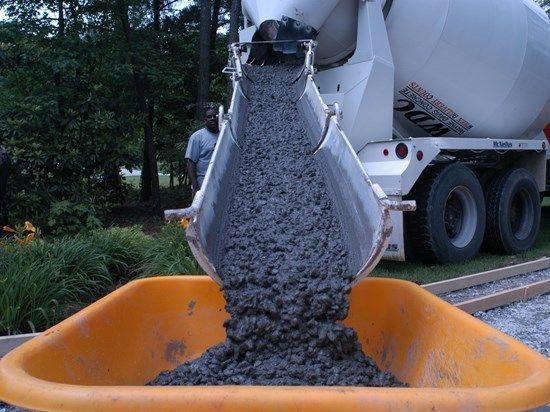

Once you’ve established a basic understanding of a simple concrete mix you can start to learn more about new concrete technologies and the true limitations of the unbelievable building material hint, there are not many. By changing the volume and variety of aggregates which you use in your cement mix you can produce several different kinds of concrete suited to different applications. Generally the goal of substituting aggregates would be to get the concrete remain consistently strong as a finished product. A few examples of concrete advanced techniques are. Even all of these options are just the tip of the iceberg for what concrete is capable of. The extreme limitations of current concrete technology being investigated and developed are transparent concrete which can show a silhouette through concrete that is meters thick. Limitations of concrete power are self supporting concrete which does not need the mechanical assistance of metal grid work. Go to the following website, if you’re searching for more information about ready mixed concrete price.

Concrete strength used to be quantified is the current component of compressive concrete strength referring to the amount of force the concrete can guarantee before failure.You may add liquid or powder pigments to your concrete to achieve interesting and dynamic colors. Frequent colors are brown, red, dark gray, tan and other similar earth tones. To get more vibrant concrete colors you can use pure white cement in place of regular cement, as well as pure white sand instead of regular sand. This white mortar mix will react well to more vibrant colors and pigments. The amount of pigment or dye that you use depends entirely on the brand that you choose. The best method is to buy from a specialty concrete supply store which will have a far better choice of quality concrete colour additives compared to your neighborhood hardware supply store.You can replace all or part of the sand in mortar mix with aggregate materials that are much lighter in character than sand. The result will be a concrete that is significantly lighter, but also vastly weaker than a sand mortar. There are many applications for lightweight concrete with many of them being decorative such as planter pots or garden statues. The most common lightweight aggregate material substitutions for making concrete.

Vermiculite which is a mineral and frequently sold as pool foundation in larger quantities from pool stores which can make a relatively strong, but compressible concrete. The insulation value of vermiculite is extremely high, over ten times as high as sand, so vermiculite concrete mixes are often used for noise dampening and insulating. Using peat partially in place of sand will result in a concrete that is much weaker than traditional mortar and even much poorer than vermiculite concrete. The texture of the concrete is somewhat earthy and finishing and detailed work can be slightly difficult by comparison with other mixes. This is another readily available and inexpensive aggregate substitutions used to reach a lightweight concrete. In addition to providing a demanding and inconsistent texture to the concrete, the wood ingrained will often stain and discolour producing an interesting and unique pattern. Too much sawdust can make the concrete unacceptably weak very quickly more so than vermiculite and peat moss.